About Milk Cooling and Storage Systems

Milk storage tanks and silos play a vital role in preserving milk quality and safety from collection to processing. Made from high-grade stainless steel, they offer consistent cooling, hygienic storage, and durability for demanding dairy environments. Key features include insulation for temperature control, easy-to-clean surfaces, and compatibility with heat recovery systems—ensuring efficiency, hygiene, and long-term performance. Below you find a range of different cooling unit designs.

The same storage vessel can also be used for storing & maintaining the temperature of several other liquids including: Water, Beer, Cream, Yoghurt, Liquid Eggs & Blood.

Milk Storage Tanks are grouped in two categories:

- Horizontal Tanks: Capacity ranging from 1000ltr to 36,500ltr

- Vertical Silos: Capacity ranging from 12000ltr to 60,000ltr

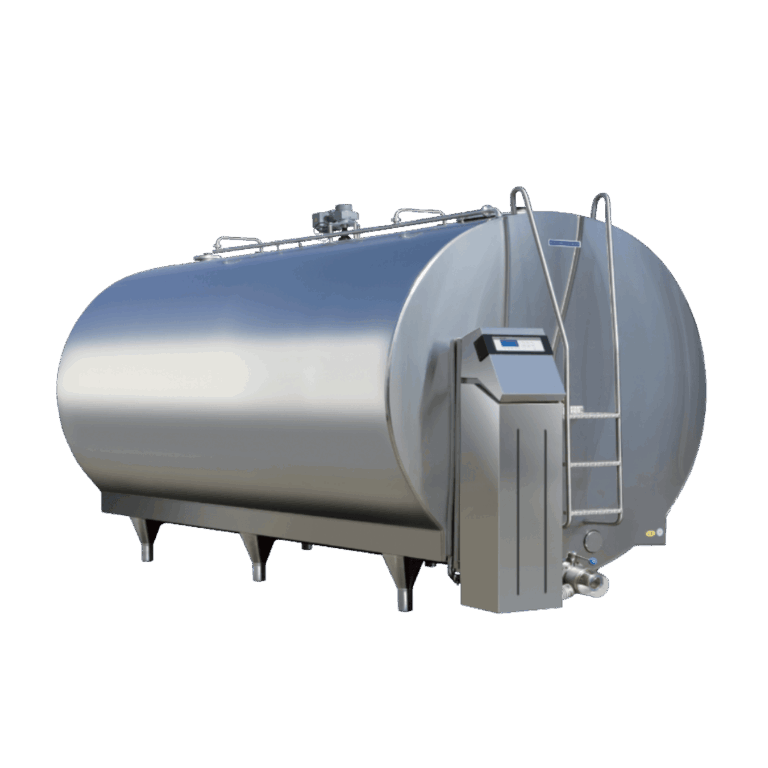

Horizontal Milk Storage Silo Tanks

Horizontal milk tanks capacity ranges from 1000ltr to 36,500ltr. The primary goal of these tanks is to reduce the temperature of milk rapidly to preserve the milks quality and maintain freshness. These tanks are manufactured from high quality stainless steel to ensure easy cleaning and quality milk cooling and storage. The tanks can be sited inside dairy rooms or external with the addition of an outdoor storage kit. Milk tanks can also be used to store and cool all types of liquids including water, beer, cream, yoghurt, liquid eggs and blood.

Vertical Milk Storage Silo Tanks

Vertical milk silos capacity ranges from 12,000ltr to 60,000ltr. The silos offer the same milk storage and cooling benefits as the horizontal tanks but with the added advantage of offering increased capacity without the need for a larger dairy. The silos can either be installed as a stand alone unit with outdoor access doors (i.e no dairy required) or located directly next to an existing dairy.

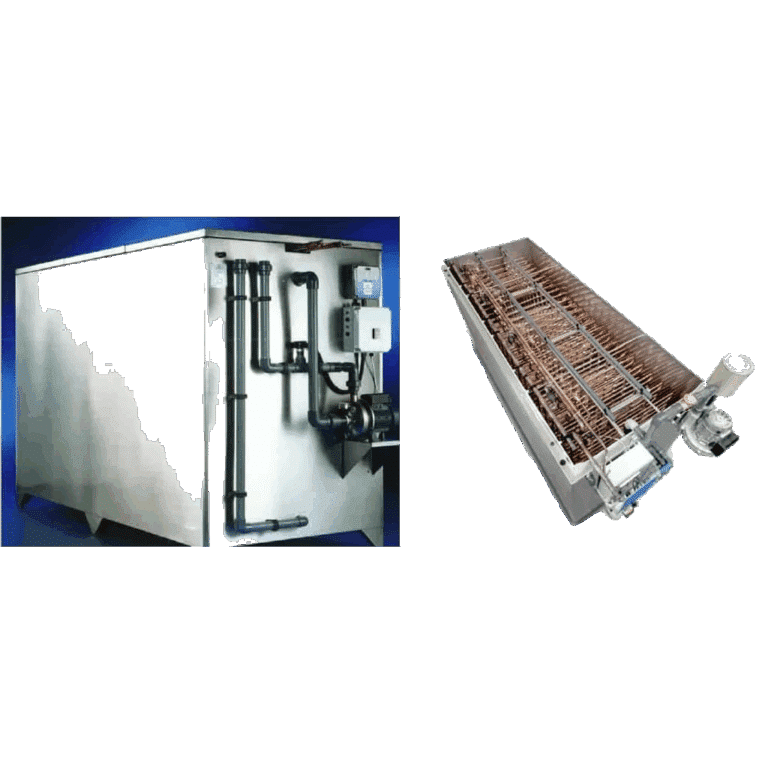

Ice Builders:

Ice builders (Thermal Store) are used in conjunction with plate coolers to provide ice water for additional pre-cooling of the milk.

Ice is formed around the refrigeration copper tubes within the energy store to provide ice water @.5degC. The water is then circulated to either a pre-cooler (plate cooler) or to the milk storage vessel to achieve rapid cooling of milk to below 4degC. The warm water is then circulated back to the energy store to be cooled down.

The system can build energy (Ice) during the night or can be timed to run during the day to pick up on solar energy.

Capacity ranging from 500Kgs of Ice to 5000kgs.

Glycol Chiller:

The chiller uses a mixture of glycol (a type of antifreeze) and water to transfer heat making it ideal for applications where the cooling liquid needs to remain liquid even at sub-zero temperatures.

Capacity ranging from 5.5Kw upwards.

Plate Cooler:

A plated heat exchanger consists of thin, corrugated stainless-steel plates, which are arranged in a stack. The corrugations improve turbulence in the fluid flow, enhancing heat transfer efficiency.

The number of plates can be adjusted depending on the required heat transfer capacity & milk flow rates.

Heat Recovery System:

Heat recovery involves the transfer of ‘waste’ heat from the hot refrigerant gases in the milk cooling system to heat water. Water temperatures of up to 60°C can be achieved from heat recovery.

Why choose DD Cooling?

Since 2007, we’ve been carrying out installations of milk cooling systems. With a team of over 30 fully qualified engineers, every project is completed to industry standards. Our work covers a wide range of sectors, from large-scale industrial to commercial installations.

Learn more about how we delivered an energy-efficient CO₂ Cooling System for Ribble Farm Fare – read the full case study here.

Who We Work With

Milk cooling and storage is essential across several sectors within the dairy and food production industries:.

- Dairy Farms

- Milk Processing Plants

- Milk Collection and Transport Services

- Manufacturers of Cheese and Yoghurt

- Food & Beverage Manufacturers

Get A Free Quote

If you work in the dairy or food production industry, or you’re a dairy farmer in need of a reliable milk cooling solution.

Proudly serving businesses across Lancashire, Cumbria and the North West for all your milk cooling tanks and storage solutions needs.

Call us today on 01772 780806 or fill out our enquiry form to get a free quote.

Download our customer brochure

Download our diamond quality partner certificate

What we’ve achieved